Copyright © Xi’An XuWu Electronic Technology Co., Ltd. All Rights Reserved. Site Map

- +86-13772111860

- xuwu-tech@foxmail.com

- Room 4108, Sanqiao Runfeng Building, Weiyang District, Xi'an

System solution:

■ The 3D slicing software on the integrated display and control industrial computer slices the printed workpiece, generates the printing trajectory G code program, and sends it to the PLC through the Ethernet interface.

■ The main PLC uses a medium-sized PLC based on the Codesys system architecture, which supports CNC subroutines internally. The G code program can be sent through the host computer interface through the Ethernet interface, USB interface, etc. The theme architecture of the equipment control is built by the PLC program.

■ The trajectory feed axis is connected to the high-performance servo system by the PLC through the high-speed EtherCAT bus to perform three-dimensional axial feed control and printing platform leveling control.

■ The PLC is connected to two temperature controllers through the RS485 interface to control the temperature of the print head and the platform respectively. At the same time, according to the different printing materials, it also realizes the control of the electromagnetic proportional valve and the status monitoring of the print head.

System advantages:

■ The control system adopts a domestically produced high-performance medium-sized PLC system with powerful functions and reliable performance, and is not restricted by the supply chain of foreign manufacturers.

■ The system is completely independently developed, and subsequent maintenance and upgrades are convenient and fast.

■ The system has high printing accuracy and is suitable for high-precision small-size workpiece printing.

Printing and packaging and lithium battery industry-slitting machine application case.

System solution:

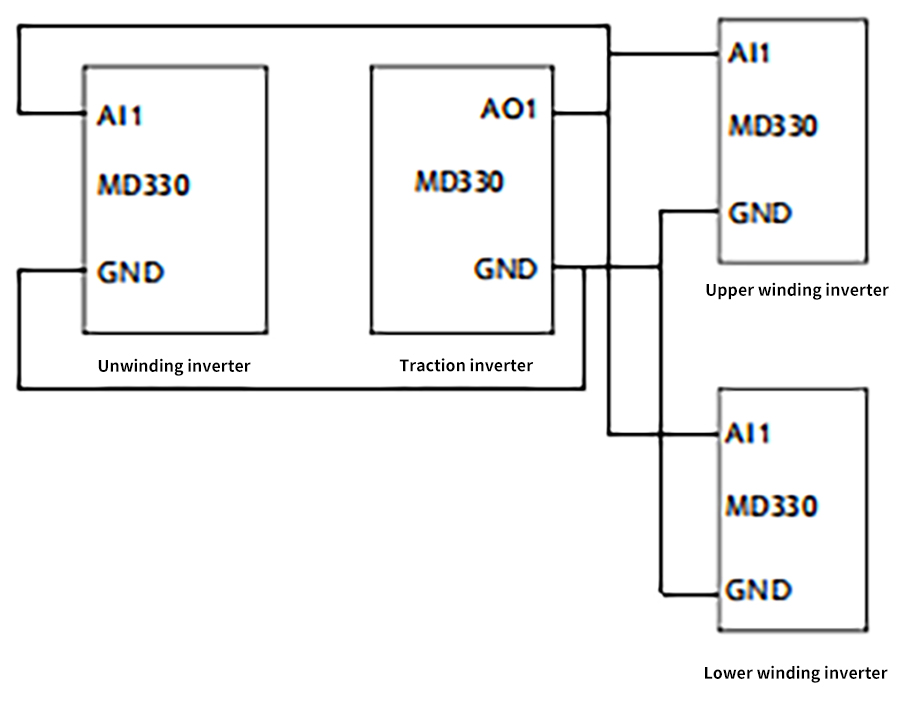

■ Slitting machine is a mechanical equipment that cuts wide paper or film into multiple narrow materials. It is commonly used in papermaking machinery and printing and packaging machinery. Its transmission system is mainly composed of a host inverter, a rewinding inverter and two rewinding inverters. The host inverter works in open-loop vector mode to control the system speed. The unwinding inverter and the two rewinding inverters work in open-loop torque mode to control the system unwinding and the upper and lower rewinding after slitting, as shown in the figure.

Solution description:

■ The host inverter uses the general inverter MD330 to control the running speed of the slitting machine. It works in open-loop vector mode. The main speed is generally adjusted by a potentiometer. Its AO1 port is used as the output of the running frequency and as the given linear speed of the unwinding inverter and the upper and lower rewinding inverters. The unwinding inverter and the rewinding inverter use the MD330 tension-specific inverter. These three inverters all work in open-loop torque mode.

■ MD330 inverter is an inverter that can realize constant tension control. The real-time roll diameter of the material roll can be obtained through the calculation inside the inverter, and constant tension control can be obtained by controlling the output torque of the inverter.

Solution advantages:

■ The solution is simple and easy to debug. In addition, the constant tension control is basically not affected by the speed, and high-speed slitting can be achieved.

■ By setting reasonable parameters for system inertia compensation, friction compensation and material inertia compensation, the speed unevenness during the startup or acceleration process caused by system inertia, friction resistance and material inertia can be compensated, and a very stable tension control effect can be obtained. In addition, the winding inverter can realize taper control to achieve the effect of tight winding.

■ It overcomes the inherent weaknesses of magnetic powder, making the control of high-speed slitting a reality and greatly improving the reliability of the equipment.

Logistics Automation System Industry-Smart Logistics Equipment Application Cases

Process and industrial environment requirements:

Automated high-bay warehouses use multi-layer steel structure shelves to form storage unit cargo grids.

Use special material handling equipment stackers, conveyors and distribution vehicles to complete material transportation. The stacker runs in the rail lane. It is the equipment with the most complex movement mode and the most important environment among all equipment. Its performance determines the quality of the high-bay warehouse system. It is the most critical equipment in the high-bay warehouse.

The movement mechanism of the stacker is composed of three main parts: the walking mechanism, the lifting mechanism, and the fork telescopic mechanism. It performs a series of coordinated work in the lane, such as horizontal reciprocating linear, vertical lifting, left and right telescopic fork picking, etc., to realize the storage unit cargo from the lane port conveyor to the designated cargo position, or from the designated cargo position to the lane port conveyor. The warehouse operation, thereby realizing the automatic entry and exit of goods together with the lane port entry and exit conveyor system.

Typical equipment:

■ Sorting equipment

Sorting equipment mainly uses machine vision systems or RFID equipment to classify products according to corresponding needs. In this type of equipment, the inverter plays some mechanical transmission and conveying roles.

■ Conveying equipment

Conveying equipment is responsible for transporting products to the required location at various stages before, during and after product sorting. This type of equipment requires the inverter to have stable operation, large starting torque, small installation volume, rich communication interfaces, and easy networking.

■ Stacker

The main function of the stacker is to store products in three dimensions according to requirements. The typical requirements for the inverter are to have a lifting function and good performance.

Advantages:

■ Huichuan's full range of products provides integrated solutions, and high-performance servo products help high-speed sorting equipment improve efficiency.

Smart Energy Industry-High-Frequency Electromagnetic Descaling and Anti-scaling Equipment Application Case

Technical principle:

Since the establishment of electromagnetic descaling and anti-scaling technology theory in the 1970s, it has been mature and widely used in the industrial field. From the technical principle, the high-energy intelligent variable frequency descaling and anti-scaling environmental protection and energy-saving device produced by our company mainly effectively applies and integrates two major technical principles: high-frequency anti-scaling and variable frequency resonance descaling. Under the action of high-frequency electromagnetic field, ions in water are polarized, causing scale crystals to be distorted and large crystal particles to be broken during high-frequency oscillation, thereby playing an anti-scaling role.

According to the above two technical principles, our company highly integrates and integrates domestic and foreign advanced technologies and software and hardware products to ensure that the high-energy full-frequency intelligent anti-scaling and energy-saving environmental protection device has achieved the following breakthroughs:

1. All circuits adopt integrated design, which greatly reduces the product failure rate and maintenance probability, and the magnetization time is as high as 48 hours or more.

2. Adopt domestic and foreign advanced industrial-grade single-chip processing chips, phase-shifted quasi-resonant converter chips and high-power, integrated insulated gate bipolar transistors.

3. The main hardware of the electrical module includes power module, electromagnetic conversion module, wireless transmission remote monitoring module, and electromagnetic coil part.

4. The power supply adopts the on-site 220V 50Hz power supply, which is converted by the power module to power the electromagnetic conversion part.

5. The modulation signal generator generates a complex frequency signal, which is added to the pipeline through the signal cable, and a molecular force dynamic interference field is generated inside the pipeline, acting on the fluid and dissolved salt molecules in the pipeline to produce a nucleation effect. The software program design adopts the most mature variable voltage and frequency conversion technology.

6. Digital filtering, digital PID, pulse width modulation and other technologies are used in the generation of frequency signals, power amplification, and the design of high-frequency power supplies and transducers.

Smart Water - Sewage Treatment Centralized Monitoring Project Application Case

Process description:

1. Water treatment equipment management

Water treatment equipment is becoming more and more professional, and professional technicians are needed to monitor and maintain the equipment, keep abreast of the equipment's on-site operating conditions, record equipment operating data in real time, and be able to grasp equipment failures at the first time, and provide timely after-sales services and arrange preventive maintenance.

2. Water platform management

The sewage control system has a large number of instruments and instruments for pump room and water quality detection, including access control, video, turbidity, residual chlorine, smoke, water immersion, energy consumption and other information monitoring. It is hoped that this information can be monitored remotely to achieve remote management of smart water services.

Solution description:

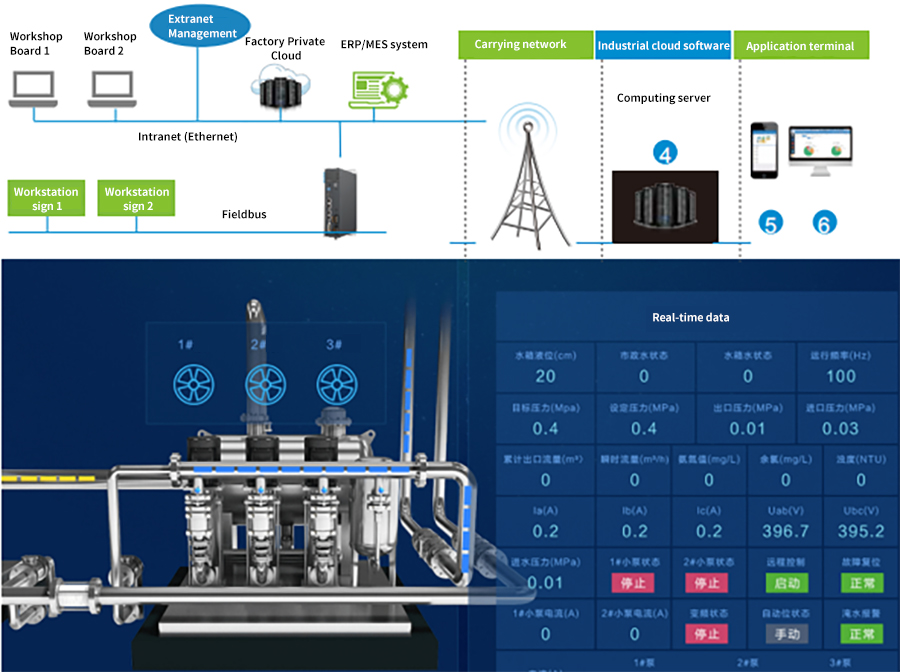

1. Users use the Internet of Things module, one or two are configured in each pump room, and connected to the on-site PLC device through the serial port to obtain operating data and sensor information.

2. The Internet of Things module transmits data to the cloud server through WIFI or 4G network.

3. Provide a cloud configuration interface, process the data, and display it on the interface, and generate corresponding reports. Users can log in to view it through a web page or mobile phone.

4. The system can set up alarm information notifications and operation reports, which can be sent to management personnel via WeChat or email.